Introduction

In the world of digital printing, laser printers have revolutionized how we produce text and images on paper. Their speed, precision, and cost-effectiveness have made them the go-to choice for both home users and large-scale enterprises. But one often-overlooked aspect of their functionality is how they actually get the toner — that fine powder — to stick to paper permanently. This isn’t just a matter of printing; it’s a carefully engineered mechanism at work.

The answer lies in a fascinating internal process within the laser printer. For those studying for IT certifications or working in the field of computer hardware, understanding this mechanism is crucial. That's why DumpsArena has prepared this in-depth guide to answer the central question: What mechanism is used in a laser printer to permanently fuse the toner to the paper?

Understanding the Basics of Laser Printing

Before diving into the fusing mechanism, it’s important to understand the broader context of how a laser printer operates. The printing process in laser printers follows a well-orchestrated sequence of steps — from charging the drum to transferring the toner to the paper. This process includes stages like charging, exposing, developing, transferring, and finally fusing.

Each of these stages plays a role, but it is the final stage — fusing — that ensures the toner remains permanently fixed to the paper. Without this step, the printed text and images would smudge or fall off. Therefore, understanding the fusing mechanism is key to understanding how laser printers deliver high-quality, permanent prints.

The Role of Toner in Laser Printing

Toner is a powder made from finely ground plastic particles, mixed with pigments and other additives. Unlike inkjet printers that use liquid ink, laser printers rely on this dry powder. The plastic content in the toner is crucial, because it must melt during the printing process to bind with the paper fibers.

This melting process doesn’t occur on its own — it needs a powerful and precise heat source. That’s where the fusing unit comes in. The fuser is the component responsible for generating the heat and pressure necessary to melt the toner and embed it into the paper. This process results in the clean, crisp, and smudge-free prints laser printers are known for.

What Is a Fuser and How Does It Work?

The fuser is the heart of the fusing mechanism. It is typically composed of two main components: the heated roller and the pressure roller. Together, they form a pair that pinches the paper as it passes through the printer. As the paper moves between these rollers, intense heat is applied from the heated roller, and pressure is added by the pressure roller.

The heated roller can reach temperatures of around 350°F (175°C) or even higher. This heat is sufficient to melt the plastic toner particles. At the same time, the pressure roller ensures that the melted toner penetrates the surface of the paper, bonding it permanently.

Once the paper passes through the fuser assembly, the toner has been effectively fused — melted and fixed — to the paper. This results in prints that are not only visually sharp but also highly durable and resistant to smudging.

The Fusing Process in Detail

To understand the fusing process further, imagine what happens as the paper exits the transfer phase in a laser printer. At this point, the paper is covered with toner that is loosely attached to its surface. If you were to touch the paper before it enters the fuser, the toner would easily rub off, leaving a mess.

The paper then travels to the fuser unit. Here, the heated roller — typically coated with a non-stick material like Teflon — rapidly raises the temperature of the toner. This causes the toner to melt. Simultaneously, the pressure roller presses the paper and the toner against the heated roller. The combination of heat and pressure causes the toner to seep into the fibers of the paper.

This action happens in mere seconds, thanks to the precision of the fuser unit’s design. After exiting the fuser, the paper is immediately ready for handling. There’s no drying time required, unlike inkjet printing.

Types of Fusing Technologies Used

Different laser printers may use variations of the fusing mechanism, depending on their brand, model, or intended use. While the traditional method involves a heated roller and pressure roller, some modern printers employ alternative fusing technologies to increase efficiency or reduce energy consumption.

One such variation is the use of ceramic heating elements that offer faster warm-up times and better energy management. Another method is the use of induction heating, where electromagnetic energy rapidly heats the roller. These newer methods help printers reduce energy usage without compromising print quality.

Despite these variations, the principle remains the same — applying heat and pressure to melt the toner and bond it to the paper.

Common Issues with the Fusing Process

Like any other component in a laser printer, the fuser can experience problems over time. Understanding these issues is essential for IT technicians, system administrators, and those preparing for printer-related certifications.

One of the most common problems is the fuser not reaching the proper temperature. If the roller fails to heat up adequately, the toner won't melt properly. This leads to prints that smear or have sections where the toner is missing.Another issue is paper jams occurring within the fuser unit. Because the fuser rollers operate under pressure and heat, any misalignment or mechanical failure can trap the paper and cause damage.

Fuser units also have a limited lifespan. They are rated for a certain number of pages before needing replacement. As the fuser wears out, the quality of the prints declines, with symptoms such as ghosting (light duplicate images) or uneven toner distribution.

Importance of the Fuser in Certification Exams

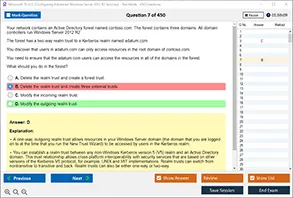

For students and professionals preparing for IT certification exams, especially those related to hardware and printer maintenance, questions about the fusing mechanism are quite common. Certifications such as CompTIA A+, HP Printer Certification, and similar exams often include questions about the laser printing process.

DumpsArena is dedicated to helping students understand not only the theoretical concepts but also the practical mechanisms like the fusing unit. Our resources are curated to ensure clarity and provide sample questions that reflect real exam scenarios. By mastering topics like this, candidates can improve their chances of passing their exams on the first try.

How DumpsArena Supports Your Learning

At DumpsArena, we believe that knowledge is power — especially when preparing for technical certifications. We are committed to delivering the best study materials, dumps, practice tests, and expert insights on printer technology, hardware components, and beyond.

Our platform features comprehensive resources that are continuously updated to match the latest exam objectives. Whether you're studying for CompTIA A+, HP Printer certifications, or vendor-specific tests, understanding hardware concepts like the laser printer fusing mechanism is vital.Every question on our platform is designed with real-world application in mind, ensuring you're not only ready for the exam but also equipped to troubleshoot issues in the field.

Conclusion

So, what mechanism is used in a laser printer to permanently fuse the toner to the paper? The answer is the fuser unit, a critical component that applies both heat and pressure to ensure the toner melts and adheres to the paper surface permanently. This process is fundamental to the high-speed, high-quality output laser printers are known for.

Understanding this mechanism isn’t just trivia — it’s foundational knowledge for anyone working in IT, hardware maintenance, or studying for certifications. At DumpsArena, our goal is to make this knowledge accessible, practical, and exam-ready.

1. What mechanism is used in a laser printer to fuse toner to the paper?

a) Inkjet mechanism

b) Electrostatic mechanism

c) Heat and pressure mechanism

d) Magnetic mechanism

2. In a laser printer, which component applies heat and pressure to the toner to fuse it to the paper?

a) Drum unit

b) Fuser unit

c) Toner cartridge

d) Print head

3. The fuser in a laser printer uses which type of heat?

a) Induction heat

b) Radiant heat

c) Infrared heat

d) Electrical heat

4. What is the role of the fuser in a laser printer?

a) To transfer the image onto the paper

b) To dry the ink on the paper

c) To melt the toner powder and bond it with the paper

d) To clean the drum

5. What is the temperature range typically used in the fuser of a laser printer?

a) 100-200°F

b) 200-400°F

c) 500-600°F

d) 800-1000°F

6. Which of the following is NOT a part of the fuser assembly in a laser printer?

a) Pressure roller

b) Heat roller

c) Drum unit

d) Fuser film

7. What happens if the fuser temperature is too low?

a) Toner may not properly adhere to the paper

b) The paper may get burned

c) The print quality improves

d) The printer will stop working

8. In a laser printer, what is the purpose of the pressure roller?

a) To create an electrical charge on the paper

b) To press the toner into the paper

c) To guide the paper through the printer

d) To clean the print head

9. Which of the following occurs during the fusing process?

a) Toner is transferred from the drum to the paper

b) Toner is melted and bonded to the paper

c) Paper is fed into the toner cartridge

d) Paper is cooled after printing

10. Which part of a laser printer carries out the image formation before toner fusion?

a) Fuser

b) Drum

c) Paper tray

d) Laser beam

Visit Dumpsarena for the latest Cisco CCNA 200-301 Exam Dumps, study guides, and practice tests to ensure your certification success!